About Us

Aegle Technology (https://aegle-technology.es) is an advanced materials innovation, commercialization, and production company.

We research and develop new solutions, bring our own, and third-party, patents to market, and have the know-how and facilities to manufacture products of the highest quality.

We are based in Barcelona, Spain, and work closely with both scientific experts and industry leaders to further technology innovation.

Introduction

BioGAS+ is the first ready-to-use additive for anaerobic digestion (AD) based on advanced materials, offered by Aegle Technology. It has obtained the highest ever-reported improvement of biogas production +285% and other significant benefits (following DIN-38414 standard)[1], with cellulose as feedstock.

Biostarter is an innovation developed by Metanogenia S.L. (Badajoz, Spain) based on high-efficiency anaerobic cell cultures adapted to the treatment of specific agricultural and food industry waste and by-products. In this case study, microbiota for slaughterhouse and oil mill by-products was selected.

Using knowledge extracted from preliminary studies, a round of BMP assays was carried out at optimized Hydraulic Retention Times (HRT) and BioGAS+ dosing (0.01% of Fe3O4NPs vs total volatile solids, w/w) in digesters with slaughterhouse by-products as feedstock. Additionally, an extra assay with goat’s dairy farm by-products (goat’s cheese whey + manure) was carried out in parallel.

Three combinations of substrate, HRT and BioGAS+ dosing were studied:

Slaughterhouse Waste:

- 0.01% BioGAS+ dosing and 31 days HRT

- 0.01% BioGAS+ dosing and 27 days HRT

Goat’s cheese whey + manure:

- 0.1% BioGAS+ dosing and 20 days HRT

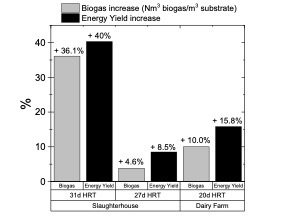

Addition of BioGAS+ yielded increases to biogas production, biomethane production, biomethane richness and energy yields for all three assays. Of special relevance are the absolute and relative increases of energy yields obtained when BioGAS+ is added.

These are remarkable results considering that BioGAS+ was added to reactors already highly optimized with the use of Biostarter adapted to each substrate and only marginal (if any) increases were expected. Higher production increases are to be expected if added to reactors which are not already optimized.

RESULTS

Slaughterhouse Waste:

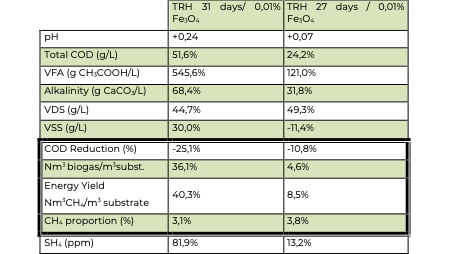

0.01% BioGAS+ dosing and 31 days HRT:

A +36% in biogas and a +40% in biomethane production per m3 of substrate vs baseline. A 59% decrease on Chemical Oxygen Demand (COD) of the digestate.

0.01% BioGAS+ dosing and 27 days HRT:

A +5% in biogas and a +9% in biomethane production per m3 of substrate vs baseline. A 62% decrease on COD of the digestate.

Table 1 summarizes the effect of adding of Biogas+ to a reactor that already works with Biostarter. In other words, what BioGAS+ contributes to Biostarter.

Goat’s cheese whey + manure:

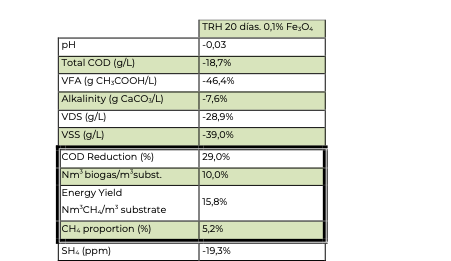

0.1% BioGAS+ dosing and 20 days HRT:

A +10% increase in biogas and a +16% in biomethane production per m3 of substrate vs baseline. A 51% decrease on COD of the digestate (in this case, a decrease of a 29% also in comparison with the “Biostarter alone” baseline).

Higher energy yields are obtained with added BioGAS+, showing an increase from 32.2 to 37.3 Nm3 methane/m3substrate. A similar effect is observed on the methane richness of the produced biogas, increasing from 67% to almost a 71%.

In this case, the addition of BioGAS+ (0.1% dose) also yielded to a noteworthy decrease of COD of a 29% when compared with the baseline without BioGAS+.

Table 2 summarizes the comparison of using and not using BioGAS+ in reactor that already works with Biostarter on the digestion of this substrate.

Conclusions

It is important to state that in all cases BioGAS+ was added to high stability reactors already working with the given feedstock and highly adapted microbiota with operational logs of over 1 year data was used as baseline.

Absolute values of energy yields obtained when BioGAS+ is added for the slaughterhouse by-products, values of 41.2 and 37.5 Nm3 methane/m3substrate for 31 and 27 days HRT respectively are obtained, compared with 29.4 and 34.5 Nm3 methane/m3 substrate when not using BioGAS+. For the goat’s cheese by-products, the mean increase is from 32.2 to 37.3 Nm3 methane/m3 substrate.

In terms of activity of the resulting digestate, decreases of COD were notable for all three assays with added BioGAS+. In the case of the digestion of goat’s cheese farm by-products, the addition of BioGAS+ (0.1% dose) also yielded to a noteworthy decrease of COD of a 29% when compared with the baseline without BioGAS+. COD values of the digestate are related to non-converted organic matter. This added to a biomethane increase of almost a 16%, makes us reassert our previous findings that BioGAS+ presents greater advantages when applied to more recalcitrant substrates.

For more information:

Please contact us for additional information and to begin your own trial of BioGAS+.

Aegle Technology SL

Rambla de Catalunya, 25, 1º

08007 Barcelona, Spain

+41 78 600 8995